EZ-EDM is a sophisticated 2 through 5 axis wire EDM system that can handle even the most difficult applications. Included are automatic machining strategies such as multi-pass contouring with stop, retract and cutoff options, and no-core-cut pocketing. The newly developed Punch and Die features help reduce workload by combining all task related operations into simplified and user-friendly dialogs. Convenient auto male/female part recognition plus access to every single wire movement via the motion record provides full control of taper and wire compensation registers at all times. The proven geometry interface now imports solids and surface models via IGES and STL. Extensive 3D surface creation and editing functions like the new Extract Cross Section command drastically ease the task of creating the Machining curves. Best CNC Wire EDM Software

What's New in Ezcam 2025 ? | Download Trial Version Now

Download Trial Version Now

CNC Programming Simplified…

EZ-EDM is a sophisticated 2 through 5 axis wire EDM system that can handle even the most difficult applications. The proven geometry interface now imports solids and surface models via IGES and STL. Extensive 3D surface creation and editing functions like the new Extract Cross Section command drastically ease the task of creating the Machining curves.

EZ-EDM is a sophisticated 2 through 5 axis wire EDM system that can handle even the most difficult applications. The proven geometry interface now imports solids and surface models via IGES and STL. Extensive 3D surface creation and editing functions like the new Extract Cross Section command drastically ease the task of creating the Machining curves.

Included are automatic machining strategies such as multi-pass contouring with stop, retract and cutoff options, and no-core-cut pocketing. The newly developed Punch and Die features help reduce workload by combining all task related operations into simplified and user-friendly dialogs. Convenient auto male/female part recognition plus access to every single wire movement via the motion record provides full control of taper and wire compensation registers.

EZ-EDM comes with a library of post processors for the most commonly used EDM machines including: FANUC, SODICK, JAPAX, AGIE, CHARMILLES, MITSUBISHI and MAKINO.

Download Trial Version NowProduct Details

General

The wide array of intuitive CAD functions are the foundation of what makes

The wide array of intuitive CAD functions are the foundation of what makes

EZ-EDM the easiest to use CAM system available today. Automatic filleting, advanced trimming commands and mathematical function plotting are just a few examples of EZ-EDM state-of-the-art CAD features. Create geometry in any plane using the Multiple User Coordinate Systems. Import IGES, DXF and VDAFS geometry files. IGES loading is optimized for importing all major CAD system files. Dynamic rubberbanding lets you preview the results of a command before completing it; and if you still make a mistake, you can undo/redo up to 25 consecutive commands.

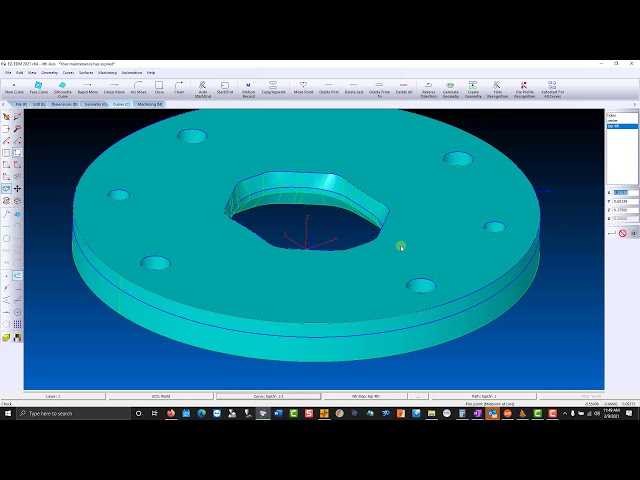

Solid and surface models can now be imported via IGES and STL. Machining curves can then easily be extracted as cross sections from all visible surfaces. Extensive 3D surface creation and editing functions are also provided. Dynamic Rotation, Panning and Zooming of all geometry and toolpaths lets you more quickly and easily change views and inspect your parts. Built-in BASIC macro language editor provides extensive macro writing capabilities, allowing end users endless customization options within the product. Postprocessor definition language supports BASIC scripting.

Solid and surface models can now be imported via IGES and STL. Machining curves can then easily be extracted as cross sections from all visible surfaces. Extensive 3D surface creation and editing functions are also provided. Dynamic Rotation, Panning and Zooming of all geometry and toolpaths lets you more quickly and easily change views and inspect your parts. Built-in BASIC macro language editor provides extensive macro writing capabilities, allowing end users endless customization options within the product. Postprocessor definition language supports BASIC scripting.

Machining

Get the most out of your wire EDM using modern machining technologies, based on several years of shop floor experience. Define multiple cuts for roughing and finishing using user definable technology database. Let the software cut back and forth or automatically create subprograms for every contour. Define single or multiple stoppoints. Easy creation of cylindrical and conical shapes for output as angular or four axis XY-UV NC code.

Get the most out of your wire EDM using modern machining technologies, based on several years of shop floor experience. Define multiple cuts for roughing and finishing using user definable technology database. Let the software cut back and forth or automatically create subprograms for every contour. Define single or multiple stoppoints. Easy creation of cylindrical and conical shapes for output as angular or four axis XY-UV NC code.

Punch and Die Design wizard lets you select pre-defined machining strategies which greatly simplifies programming. It includes a new Taper & Land option that lets you quickly enter in angles and land height for all possible combinations. New auto-sequencing options give you full control over the order of rough, finish and cut-off operations for multiple or single profiles. 3D Solid Model Preview function lets you watch your part being cut from a solid block of material. A toggle lets you switch between the cavity, cut-out, or wire path pieces, and you can dynamically rotate, pan and zoom the model for full inspection.

Punch and Die Design wizard lets you select pre-defined machining strategies which greatly simplifies programming. It includes a new Taper & Land option that lets you quickly enter in angles and land height for all possible combinations. New auto-sequencing options give you full control over the order of rough, finish and cut-off operations for multiple or single profiles. 3D Solid Model Preview function lets you watch your part being cut from a solid block of material. A toggle lets you switch between the cavity, cut-out, or wire path pieces, and you can dynamically rotate, pan and zoom the model for full inspection.

Post Processing

EZ-EDM comes with a library of post processors for the most commonly used EDM machines including: FANUC, SODICK, JAPAX, AGIE, CHARMILLES, MITSUBISHI, and MAKINO. And you can easily build your own post-processor files for virtually any CNC control with the included EBuild utility. A new EZ-DNC G-code text editor with DNC RS232 communications is also included.

Product Comparison Chart

| EZ-MILL Express | EZ-MILL | EZ-MILL Pro | EZ-TURN Express | EZ-TURN | EZ-EDM | |

|---|---|---|---|---|---|---|

| Import/Export DXF/DWG/IGES | ||||||

| Import STEP/ACIS/PARASOLID/VDAFS/STL | ||||||

| Import SOLIDWORKS/RHINOCEROS | ||||||

| Wireframe Geometry Creation and Editing | ||||||

| Basic Dimensioning | ||||||

| Basic Engraving | ||||||

| Gears/Splines/Cams Geometry Creation | ||||||

| Multiple Layers and Colors | ||||||

| Multiple Construction / Machining Coord. Sys. | ||||||

| Silhouette Boundary Curve Creation | ||||||

| Basic Surface Creation and Editing | ||||||

| Advanced Surface Creation and Editing | ||||||

| Copy/Paste from Alibre (Solids Modeling & Design) | ||||||

| Single and Multi-pass Profiling | ||||||

| 3D Profiling | ||||||

| Thread Milling | ||||||

| ZigZag Pocketing | ||||||

| Offset Pocketing | ||||||

| UltraHSM Pocketing (High-Speed ) | ||||||

| Curve Machining Wizard | ||||||

| XYUV - Form Tool - Punch/Die Cycles | ||||||

| Tapered Tool & Wall Support | ||||||

| Standard Holemaking Canned Cycle Support | ||||||

| Rotary Axis Indexing (4th & 5th Axis) | ||||||

| Rotary Axis Wrapping | ||||||

| Equidistant Finishing | ||||||

| Automatic Constant Z Re-Roughing | ||||||

| Multi-Surface | ||||||

| Constant Z Roughing | ||||||

| Constant Z Finishing | ||||||

| Equidistant Re-Finishing | ||||||

| Pencil Milling | ||||||

| Rough Turning/Facing/Boring from Cylindrical Stock | ||||||

| Rough Turning/Facing/Boring from Custom Stock | ||||||

| Canned Cycle Roughing Support | ||||||

| Custom Auxiliary, Bar Pull and Cut-Off Cycles | ||||||

| Drilling/Threading/Grooving/Long Hand&Canned Cyc. | ||||||

| Toolpath Repetitions - Translate/Rotate/Mirror | ||||||

| Graphic Toolpath Verification Plotting | ||||||

| Solids Simulation Toolpath Verification | ||||||

| Dynamic Viewing Controls | ||||||

| Tool Library | ||||||

| Material Library | ||||||

| Integrated Spreadsheet Operations Manager | ||||||

| Library of Posts | ||||||

| Post Processor Editor | ||||||

| Visual Basic Automation Interface |

-

EZ-CAM v2024: "Learn How to be an EZ-EDM PRO!" - WEBiNAR #EZCAM #EZEDM

-

Experience the Cutting-Edge Features of EZCAM 2023 : CNC Milling, CNC Lathe, EDM

-

New EZ Web Tools: Full Backup + Remote Work + Remote Support

-

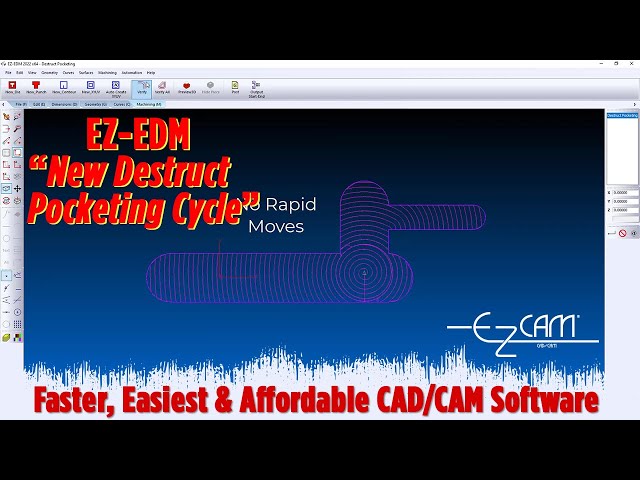

New Destruct Pocketing Cycle in EZ-EDM - Wire EDM Pockets - Best Wire EDM Software - EZ-CAM CAD/CAM

-

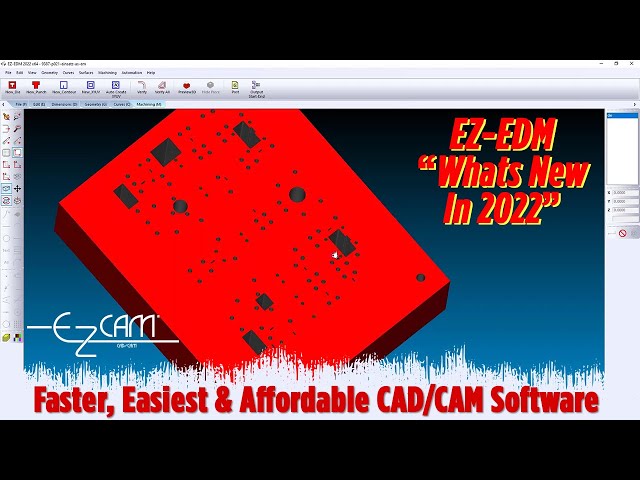

Whats New in EZ-EDM 2022 - CNC Wire EDM Affordable Cad / Cam Software EZ-CAM

-

New Destruct Pocketing cycle in EZ-EDM avoids rapids and returns to the start point - EZ-CAM

-

EZ-EDM new DIE method S8: Multiple Profiles :: Main Cut All, Finish (2-n) All - Affordable CAD/CAM

-

How to Update Toolpaths with Alibre - EZ-CAM Associativity - Easiest & Affordable CAD/CAM Software

-

What's New In Ezcam2022 ? - CNC Milling - CNC Turning - CNC Wire EDM - Affordable & Powerful CNC

-

Best CNC Software Key Benefits of EZ-MILL, EZ-TURN, EZ-EDM & Introduction to EZ-CAM

-

Fully Automated Wire Path Programming with EZ EDM - EZ-CAM CNC Wire EDM Simplified -CAD/CAM Software

-

EZ-EDM New Automation Features at work for 4th Axis Top and Bottom Machining - CNC Wire EDM -CAD/CAM